Mebotics Debuts World's First Machine Shop in a Box

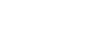

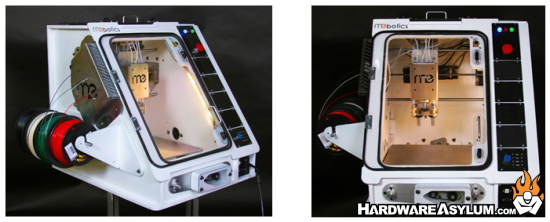

Somerville, Mass. – August 28, 2013 – Mebotics, LLC is launching the Microfactory – already gaining notoriety as the “world’s first machine shop in a box” – on Kickstarter this week. The Microfactory will be the first widely-available machine to marry both additive and subtractive manufacturing, integrating machining and 3D printing into a safe, self-cleaning, networkable unit. The company has announced a $1 million fundraising goal.

The Mebotics team conceived, designed and built the Microfactory over the past year. “After putting so much effort into what we truly believe to be a revolution in accessible 3D printing technology, we’re thrilled to be ready to share it with the public,” said Jeremy Fryer-Biggs, one of the four co-founders of Mebotics. “The beauty of the Microfactory is its broad range of applications. Imagine being able to do most of your prototyping work, including machining parts and etching circuit boards, on a single machine.”

The Microfactory contains four printing heads on two separate heaters, plus a milling head. This allows it to print in four colors of the same material, or two colors of two different materials, on the same part. The milling component is capable of cutting and etching wood, plastic and some metals (with optional upgrade). Its user-friendly features are designed to bring more industrial capability to smaller workshops. They include a vacuum port to remove all the debris created by cutting, an air filter, prominent emergency-stop button, covered belts and motors (to keep clothing from getting caught by moving parts) and a noise-reducing housing (to keep late-night makers from getting caught by angry neighbors!). The Mebotics team drew on many years experience building and using industrial tools to create an easy-to-use machine for people who are serious about making.

Unlike many other 3D printers, the Microfactory contains a full on-board computer, which gives it many unique capabilities. With its Internet connectivity, the Microfactory will allow users to watch the progress of jobs in real-time from a phone or tablet, start and stop jobs remotely, or network machines together for more efficient production. All of the software components of the Microfactory are open-source, and the hardware is designed to be upgraded and modified by more intrepid users: The gantry is intended to support the attachment of different heads, and the entire left wall of the machine is removable to support alternate modules.

“The Microfactory is an open platform designed to be adaptable to the needs of its users,” Fryer-Biggs explained. “Printing and milling seemed like the most obvious initial combination, but we envision people going a lot further -- whether it’s adding a 3D scanning head, converting it to a computerized paint-shop, or making an innovative food-extruder.” He adds, “If anybody does use it for making awesome new food, they’re invited to bring it by the shop.”

Mebotics aimed to make the Microfactory the ultimate all-in-one factory for small businesses -- biotech and design firms, architects, teachers --- as well as artists, early adopters and avid hobbyists. “We’ve tried to leave the door open for even some really extreme applications. With WiFi connectivity, the Microfactory can be run from the middle of nowhere: a research station in Antarctica, a basecamp in the Himalayas, or even a military outpost could download a file and make replacement parts on the spot.” This creative spirit is embodied in the company’s slogan: Ask Me What I Can’t Make.

To learn about the full range of machine specs and available upgrades, visit the Microfactory page on www.kickstarter.com. Backers can donate from $1-$9,995, pre-ordering the Microfactory starts at $3,995. To learn more, visit www.mebotics.com/microfactory.html and follow Mebotics on Facebook at www.facebook.com/mebotics.